Advantages

Particular planning security

The KR 16 offers absolute planning security, consistent quality and very high availability. Its robustness protects it against aging – and helps you avoid investment and maintenance costs.

Application-specific variety

Ceiling, floor or wall mounting – as a Cleanroom variant or with an arm extension: the range of types and the variety of equipment of the KR 16 make it a versatile robot for the low payload category and with a wide range of potential applications.

Comprehensive space savings

Thanks to its minimized disruptive contours and its streamlined, compact design, the KR 16 convinces with high accessibility even in confined spaces. It strikes a perfect balance between space requirements, reach, weight, speed and energy consumption.

More

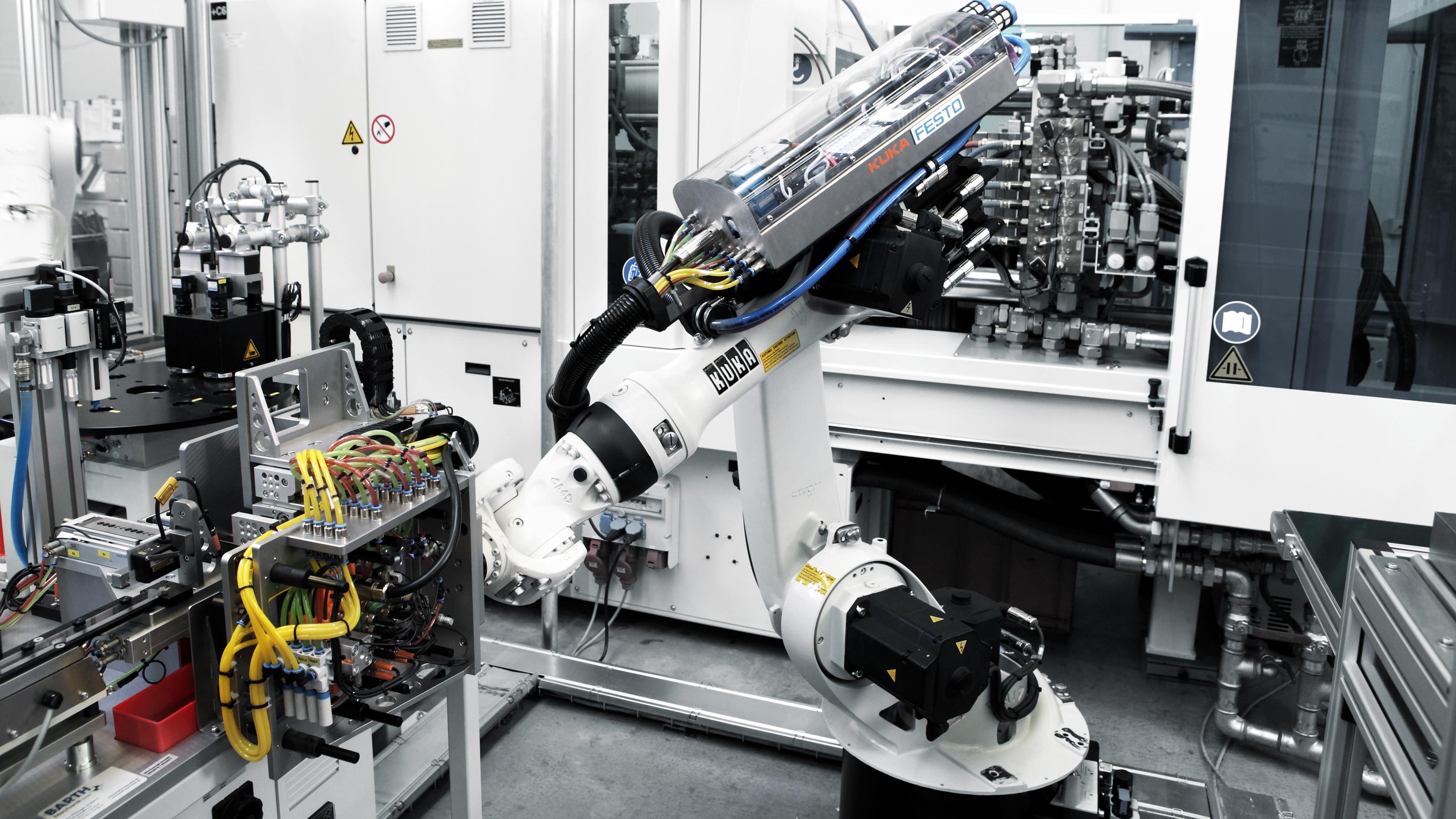

KR 16 as a shelf-mounted robot

The KR 16 is also available as a shelf-mounted robot. The shelf-mounted variant can be installed on a machine – thereby increasing its work envelope depth. At the same time, its compactness results in a small size. This is particularly useful for loading and unloading machines. The low base frame increases its reach. Lifting distances are also shorter. This massively reduces cycle times in machine tending and at the same time increases repeatability.

KR 16 as a Foundry variant

The KR 16 is powerful – even at extreme temperatures. This is made possible by the Foundry variant. It is thus ideal for operation at die-casting and injection molding machines and in other working environments with high temperatures. The KR 16-2 F, for example, is highly popular in the glass industry, where it is entrusted with a challenging combination of tasks. It handles hot, fragile glass parts with the utmost precision and care, even at high ambient temperatures.

KR 16 as a Cleanroom variant

With the Cleanroom variant of the KR 16, we offer the perfect industrial robot for applications requiring maximum sterility and freedom from particles. The KR 16 CR has a specially painted and ground surface which prevents the build-up of particle deposits. We have also modified the seals to avoid abrasion. It is optimally suited to all areas with high hygiene standards, such as medical technology or food processing.

KR 16 variant with extended arm

The KR 16 boasts an unbeatable reach of 1,611 millimeters with a payload of up to 16 kilograms. You want even greater reach? If so, the variant with an arm extension is perfect for you – and perfect for applications in which a long reach with a low payload is of decisive importance. The extended, streamlined arm enables an even larger workspace with a reach of up to 1,911 millimeters.

Reviews

There are no reviews yet.