Advantages

Wide spectrum

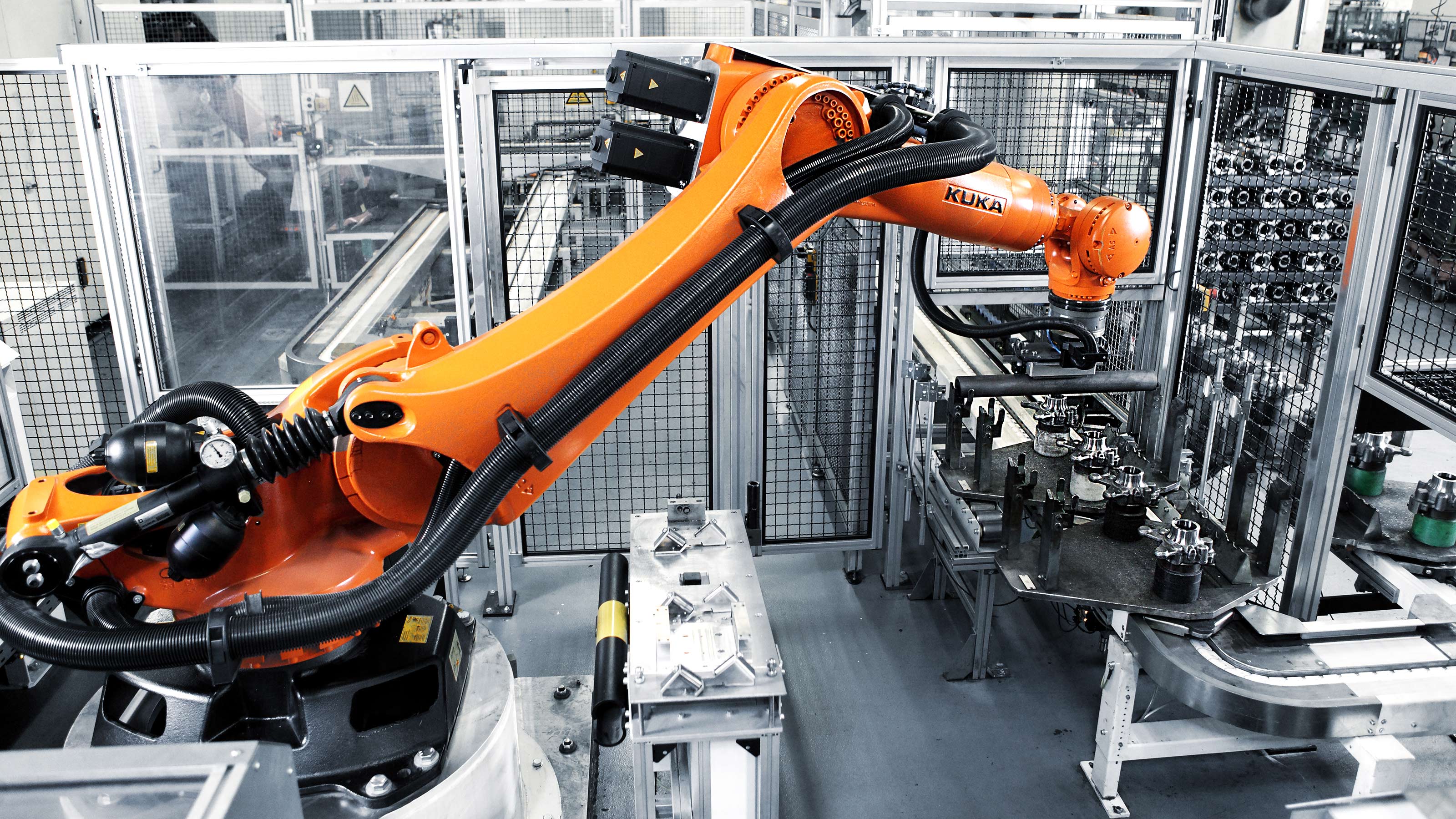

The KR QUANTEC prime achieves the perfect balance between payload and reach and opens up a wide range of potential applications. Yet spot welding is the prime’s specialty.

Fast cycle times

The KR QUANTEC prime stands out due to its robust design, yet it is extremely lightweight. It is optimized to achieve fast cycle times by way of high rates of acceleration. This is how it delivers outstanding process results.

Low maintenance requirements

The KR QUANTEC prime fits into every concept. It only requires a small amount of floor space. Even the maintenance outlay has been reduced to a minimum.

Energy-efficient and robust

The KR QUANTEC prime has a very small ecological footprint. Its compact base frame provides a firm footing and a hole pattern that is consistent with the rest of the KR QUANTEC series.

Reviews

There are no reviews yet.